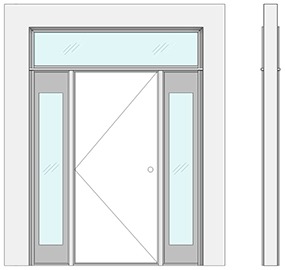

Single Door with Sidelites and Transom Installation Guide

Before you begin...

Required Tools

Unpacking your Entry System

Preparing your Rough Opening

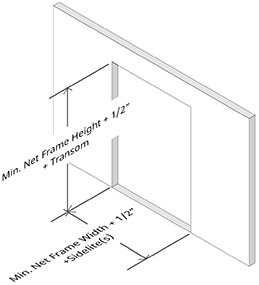

- Check the dimensions of the rough opening.

The opening should be at least 1" wider than the net frame size plus any sidelites & 1/2" taller than the net frame size plus any transoms. - Check that the floor beneath the sill is level.

- Check that the rough opening is plumb and square.

Your opening may look different than the figure depending on the door to be installed.

Installing your Entryway

Step 1: Constructing the Frame

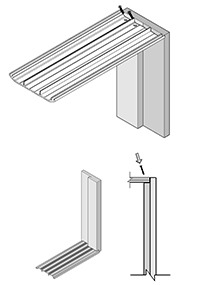

- Identify and remove the two side jambs, the header, and the sill.

- Remove the screws from the header and sill.

- Attach the header and sill to one side jamb with the provided screws, applying silicone to the joining faces.

- Attach the other side jamb to the header and sill with the provided screws, applying silicone to the joining faces.

- Check that the frame is properly assembled, square, and plumb.

Your frame may look different than the figure depending on the door to be installed. The number of hinges and screws vary based on the dimensions of the door.

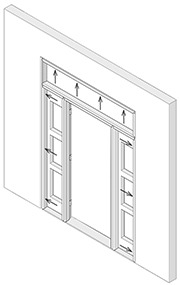

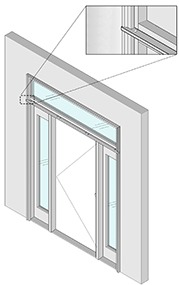

Step 2: Assembling the Frame System

- Attach the frame to the sidelite(s) with the appropriate screws (not provided) through the side jambs of the frame, and in the opposite direction through the side jambs of the sidelite(s).

Be sure to screw through shims. - Attach the transom with the appropriate screws (not provided).

Screws affix the frame firmly into place - The amount and locations you need may vary.

Step 3: Inserting the Assembly

- Apply silicone to the sub-floor beneath where the sill will sit.

- Check that the height of the interior flooring will sit beneath the sill.

- Lean the assembly into the rough opening, making sure the door will swing the appropriate way.

The door will swing towards the side that the hinges will be visible from. - Check that the sill is level.

- Lean the assembly into the rough opening, making sure the door will swing the appropriate way.

Your assembly may look different than the figure depending on the door to be installed.

Step 4: Securing the Assembly

- Hammer shims between the frame + sidelite(s) and the rough opening until the assembly is tightly installed.

Shims should be paired opposite one another on either side of the frame. - Check that the installed assembly is plumb and level.

Shims are required to keep the frame rigid and in place - the amount and locations you need may vary.

Step 5: Attaching the Assembly

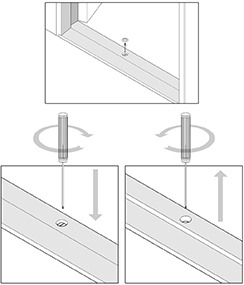

Step 7: Adjusting the Sill Height

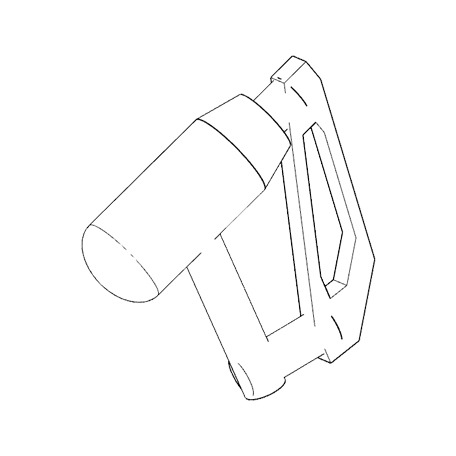

- Pry off the adjustment cap from the sill and, using a screwdriver, adjust the sill height to create a proper seal.

There may be more than one screw to adjust on the sill. - Replace the adjustment cap.

- Assure the door swings freely and closes tightly against the weatherstripping.

If your door system is outswing, there will not be an adjustment cap.

Step 8: Cutting the Brickmolding

- Identify the provided brickmolds.

The two longer pieces will cover the gap between the side jamb and the rough opening.

The shorter piece will cover the gap between the header and the rough opening. - Using the height of the frame as reference, mark the desired height of he inner brickmold.

- With a speed square, scribe a 45° line from the previous mark out towards the extra material and cut along the drawn line.

- Repeat, mirrored, for the other long piece of brickmold.

- On the shorter brickmold, mark the corners of the width of the frame.

- With a speed square, scribe a 45° line from the previous marks towards the extra material and cut along the drawn line.

Trim for Door & Transom Entryway with an overall height over 8'

Step 9: Attaching the Brickmolding

- Affix both long pieces of brickmold to the external sides of the doorway with finishing nails and apply silicone to the joining faces.

Make sure to cover the gap between the rough opening and the frame. - Affix the shorter brickmold to the external top of the doorway with finishing nails and apply silicone to the joining faces.

Make sure to cover the gap between the rough opening and the frame.

Your brickmold may look different than the figure depending on the door to be installed. Use as many finishing nails as needed to properly secure the brickmold.

Step 10: Cutting the Casing

- Identify the provided casing.

The two longer pieces will cover the gap between the side jamp and the rough opening.

The shorter piece will cover the gap between the header and the rough opening. - Using the height of the frame as reference, mark the desired height of the casing across the piece and cut.

- Repeat, mirrored, for the other long piece of casing.

- On the shorter casing, mark the corners of the width of the frame across the piece and cut.

Step 11: Attaching the Casing

- Affix both long pieces of casing to the internal sides of the doorway with finishing nails and apply silicone to the joining faces.

Make sure to cover the gap between the rough opening and the frame. - Affix the shorter casing to the internal top of the doorway with finishing nails and apply silicone to the joining faces.

Make sure to cover the gap between the rough opening and the frame.

Your casing may look different than the figure depending on the door to be installed. Use as many finishing nails as needed to properly secure the casing.

Step 12: Cutting the Horizontal Mullion Cover(s)

- Identify the provided mullion cover(s).

- Using the height of the brickmolding or casing as reference, mark the desired height of the mullion across the piece and cut.

The mullion should span the length of the entryway and terminate into the brickmolding or casing - Repeat for any additional mullions.

The horizontal mullion(s) will cover the gap between the transom and the frame / sidelites.

Step 13: Attaching the Horizontal Mullion Cover(s)

- Affix the cut piece(s) of mullion cover, interior and exterior, horizontally between the transom and the frame/sidelite(s) with finishing nails and apply silicone to the joining faces.

Make sure to cover the seam between the transom and the frame/sidelite(s).

Your mullion cover(s) may look different than the figure depending on the door to be installed. Use as many finishing nails as needed to properly secure the mullion cover(s).

Step 14: Cutting the Vertical Mullion Cover(s)

Step 15: Attaching the Vertical Mullion Cover(s)

- Affiz the cut piece(s) of mullion cover, interior and exterior, between the sidelites or transom and the frame with finishing nails and apply silicone to the joining faces.

Make sure to cover teh seam between the sidelites/transom and the frame.

Your mullion cover(s) may look different than the figure depending on the door to be installed. Use as many finishing nails as needed to properly secure the mullion cover(s).

Disclaimer: This installation guide does not cover all situations, variations, details, or scenarios concerned with the installation, operation, or maintenance of your entry system, nor does it claim to. These instructions are designed to provide general assistance in the installation of your entry system. Always consult a professional to ensure proper treatment for your door and your environment. Warranty available at www.doornmore.com.